Advanced IMI Systems

It’s inherent in human nature to adapt and evolve, and machines are no different. So where operators once instructed our machines with Human Machine Interfaces (HMI), we have now begun rolling out Intelligent Machine Interfaces (IMI).

With new features, greater connectivity and enhanced user experience, IMI is a powerful and scalable platform that works in harmony with the operator and advises them in return.

IMI features include:

> Better product quality with predictive service intervals

> User friendly interface with video instructions

> Complete transparency into your machine conditions

> Adapts easily to your needs

> Remote condition awareness at your fingertips

Condition Monitor

Multi-device access

Video instructions

Performance monitor

Evolving upgrades

Augmented Reality

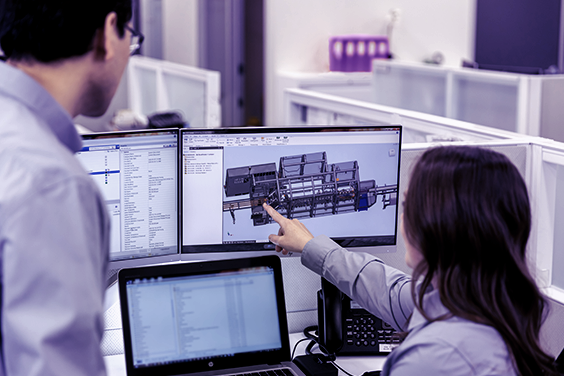

Augmented Reality (AR) has a substantial impact on your machine’s lifecycle. Whether it’s material handling or distribution, servicing or maintenance, we harness AR to prevent faults and increase uptime.

For example, we can carry out virtual testing of your machine before going live in the factory, helping to enhance your green credentials by reducing your travel footprint.

Digital Twinning

Detailed data collection enables precise monitoring of your equipment’s condition. It also allows us to create a virtual copy of your machine and production line for virtual testing. This means you can familiarise yourself with your packaging machinery before delivery and installation.

A digital twin can also be used for training our engineers to ensure we deliver the best service possible.

Microsoft HoloLens

Smart Glasses

With an eye towards automation, we utilise wearable technology in everyday situations, helping to revolutionise the manufacturing industry.

Smart glasses allow us to optimise our operations by projecting customers’ machine status and dialog messages directly into our technician’s field of vision. This efficient process ensures minimal downtime and less risk of serious damage to your equipment.

How our ecosystem builds yours

We don’t just build machines. We create automation ecosystems to develop and optimise your manufacturing process.

Our end-to-end capabilities help leading Food & Beverage, Health & Personal Care, Pharmaceutical and Consumer Goods businesses thrive in a changing world.